Top Trends in Home Decor Featuring Fashionable and Functional Copper Products

The Relevance of High Quality in the Production of Copper Products

The importance of high quality in the production of copper items prolongs far past simple conformity; it is essential to enhancing performance across various markets. Top quality copper not just enhances conductivity yet additionally assures sturdiness and reliability, which are important in applications ranging from electronic devices to auto systems. Nevertheless, the effects of inadequate manufacturing techniques can resound with prices and security standards, ultimately influencing client trust. As we discover the complex nature of high quality, the concern emerges: just how can makers balance these difficulties to achieve quality?

Influence On Product Performance

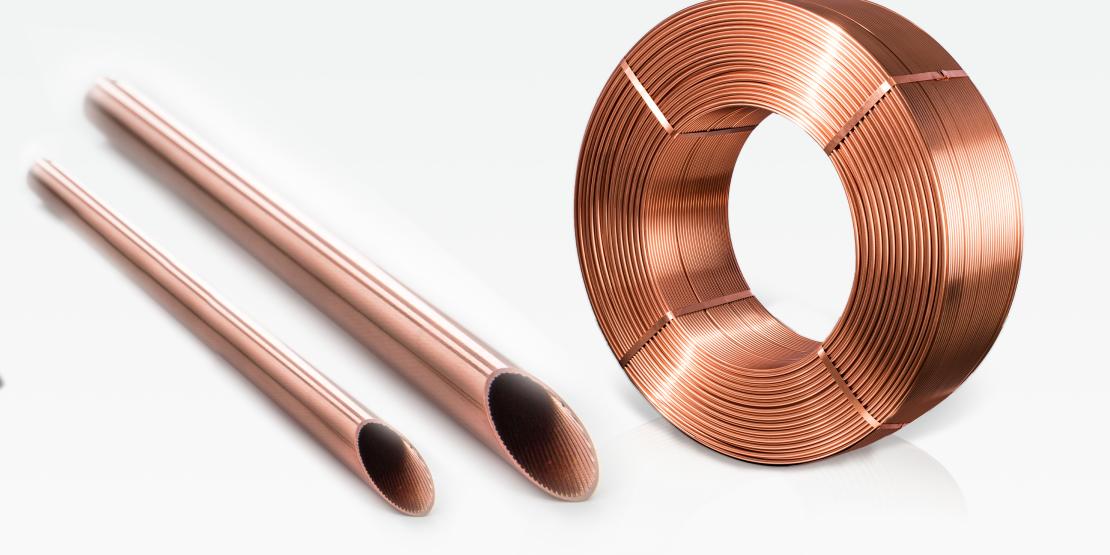

The top quality of copper products plays a critical function in determining their total performance in numerous applications. Top notch copper exhibits exceptional electric conductivity, thermal conductivity, and deterioration resistance, which are important attributes for sectors such as electronics, building and construction, and automobile.

In addition, the mechanical residential or commercial properties of copper, including ductility and tensile stamina, significantly influence its performance in making processes. Copper products that meet rigorous top quality criteria can withstand significant stress without flawing, thereby enhancing longevity and lowering the chance of failing in requiring settings.

Furthermore, the surface area coating of copper items influences their performance. A smooth, well-treated surface area can prevent oxidation and various other forms of degradation, eventually prolonging the life of the part. In summary, the top quality of copper items straight affects their capability, dependability, and durability across various markets, making it important for makers to stick to strenuous top quality control procedures throughout the manufacturing process.

Price Effects of Poor Quality

Purchasing premium copper products is important, as the price implications mediocre can be substantial for end-users and suppliers alike. Low quality copper can result in enhanced failing prices, causing expensive fixings and substitutes. Manufacturers may deal with significant downtime as defective items require remembers or remodel, disrupting production timetables and influencing total efficiency.

From an end-user perspective, the effects are similarly serious. Poor-quality copper can cause inefficiencies and boosted functional costs, as tools might need more constant upkeep. Ultimately, the first savings gained from picking lower-quality copper items can be overshadowed by these long-term expenses, making the quest of quality not simply an issue of efficiency, however an important economic consideration in the manufacturing market.

Safety and Compliance Criteria

Making certain safety and security and conformity requirements in the manufacturing of copper products is crucial to maintaining functional stability and shielding both employees and customers. The production procedure must stick to stringent regulations stated by companies such as the Occupational Security and Health Administration (OSHA) and the Environmental Protection Firm (EPA) These regulations describe important security techniques, including correct handling of basic materials and waste monitoring, making sure a secure work environment.

Additionally, conformity with industry requirements such as ASTM International and ISO qualification is vital. These organizations supply standards that help makers apply ideal methods in quality control and safety and security actions. Regular audits and evaluations should be performed to guarantee adherence to these requirements, as anchor non-compliance can cause unsafe problems and possible lawful implications.

Customer Depend On and Complete Satisfaction

Trust and fulfillment amongst consumers play an essential function in the success of copper item makers (Copper Products). Top quality copper items not just satisfy strict industry criteria yet likewise fulfill consumer expectations, fostering commitment and repeat company. When clients are positive in the top quality of the products they buy, they are more likely to create a long-lasting connection with the maker, which can lead to referrals and favorable word-of-mouth

To construct this count on, manufacturers should focus on quality assurance throughout the production process, making certain that each copper item fulfills or surpasses requirements. Openness in making practices, paired with dedication to client service, enhances the understanding of integrity. Additionally, prompt distribution and responsiveness to customer queries considerably boost complete satisfaction degrees.

Client comments should be actively looked for and integrated into product advancement cycles to constantly enhance offerings. Involving customers in dialogue concerning their choices and requirements cultivates a feeling of collaboration, more solidifying their rely on the maker. Eventually, a credibility for quality and customer-centric methods distinguishes effective copper product producers in an affordable market, preparing for enduring client connections.

Long-term Organization Success

A supplier's commitment to high quality is essential to achieving long-term company success in the affordable copper products market. High-quality items foster consumer commitment, guaranteeing repeat service and favorable recommendations that drive development. In a sector where integrity and efficiency are critical, business that focus on quality over cost-cutting procedures are most likely to stand apart.

Moreover, consistent quality reduces the event of flaws and remodel, bring about reduced functional costs and enhanced efficiency. This streamlined production procedure enables manufacturers to allot sources successfully, permitting for investments in advancement and technology. Services that adjust to spend and market changes in quality renovations are much better placed to meet Recommended Site progressing customer needs.

In additional resources addition, maintaining rigorous top quality requirements improves a business's credibility, bring in possible collaborations and brand-new clients. A durable online reputation for high quality can work as a differentiator in crowded markets, opening doors to lucrative contracts and collaborations.

Inevitably, an unfaltering dedication to top quality not only ensures compliance with sector guidelines but likewise cultivates a lasting company design. By embedding top quality into every element of the manufacturing procedure, companies can secure their place as leaders in the copper products market, leading the way for enduring success.

Conclusion

In conclusion, the relevance of top quality in copper item production is vital. As industries increasingly depend on copper for critical applications, preserving rigorous quality control is essential to safeguard a competitive advantage and maintain a credible market presence.

The significance of high quality in the production of copper products prolongs much past simple compliance; it is indispensable to optimizing efficiency throughout numerous industries. In recap, the high quality of copper items directly impacts their performance, integrity, and long life across various markets, making it imperative for manufacturers to adhere to strenuous top quality control measures throughout the production process.

A supplier's dedication to high quality is integral to attaining long-lasting business success in the affordable copper products market.